MOLD DESIGN AND TOOLING

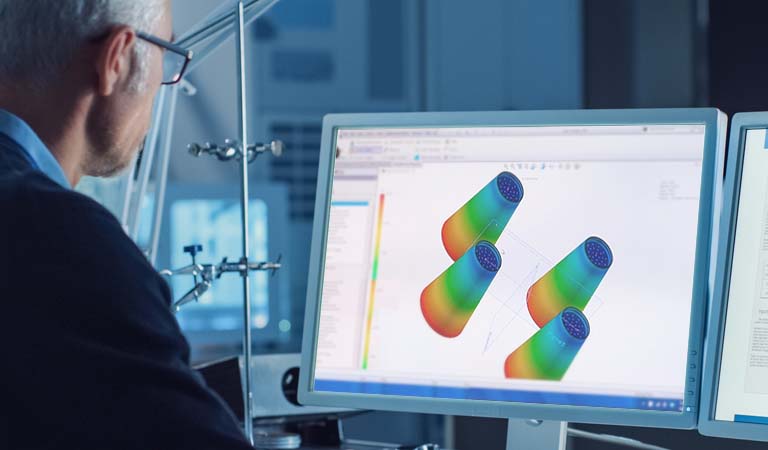

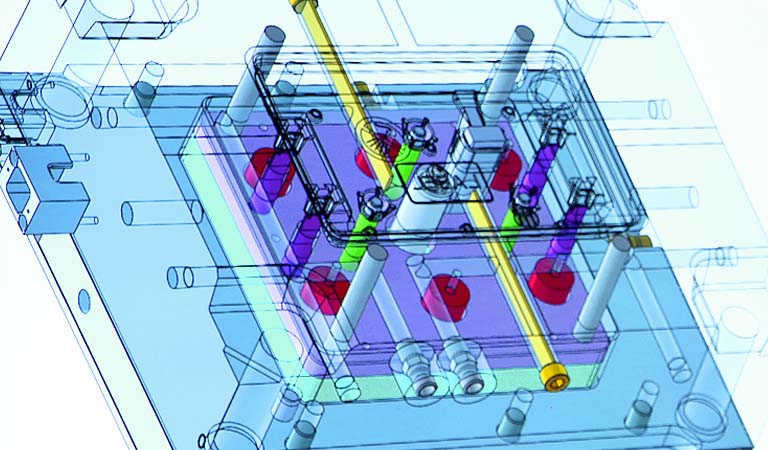

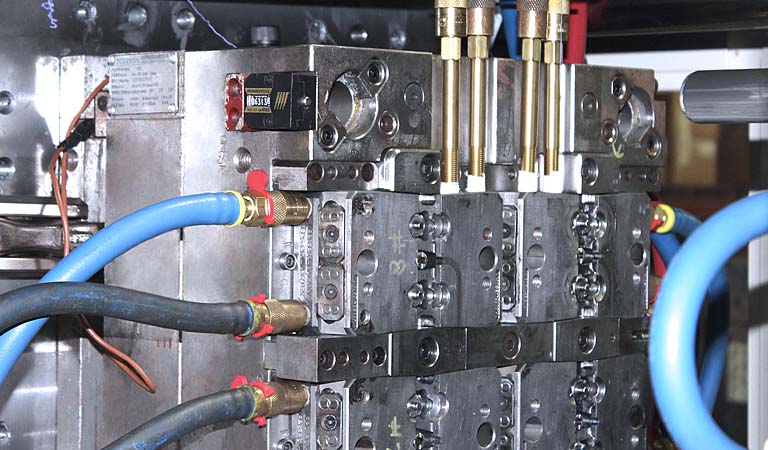

In-house expertise ensures quality right from the start

Improve part quality, reliability, and manufacturability. Get to market quicker. We know successful parts start with a well-designed mold. With in-house mold design and tooling expertise, deep knowledge in a range of materials, application knowledge, and capabilities, we build custom injection molds and guide your products from design through production.