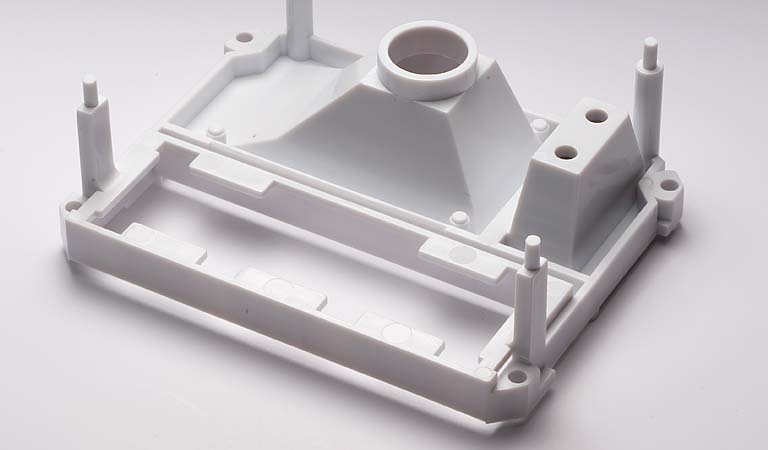

TIGHT TOLERANCE

Accuracy to satisfy customer demands

Meet the precision expectations of your customers. We use the most advanced custom plastic injection molding machines to achieve the extremely tight tolerances required in many industries, including aerospace, medical, military, industrial, technology, and consumer.