3D PRINTING

A faster alternative to injection molding

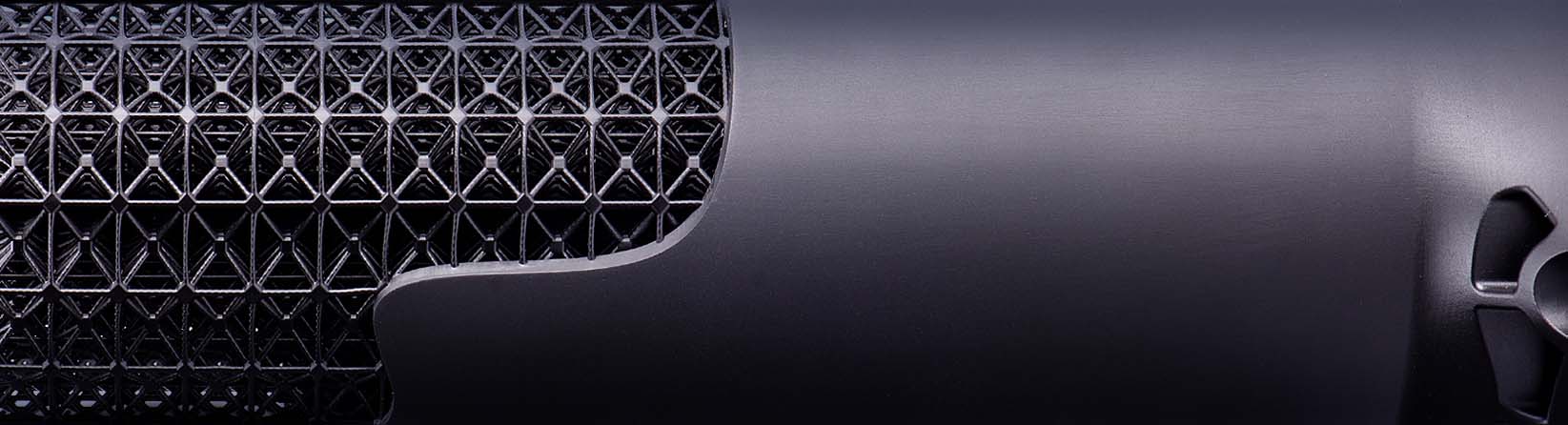

An ideal solution for prototyping and low-volume production, our 3D-printing capabilities give us the ability to manufacture durable, high-precision parts in small runs.

An ideal solution for prototyping and low-volume production, our 3D-printing capabilities give us the ability to manufacture durable, high-precision parts in small runs.

As part of the Carbon® Production Network, we have a digital manufacturing platform that offers a faster process and creates high-quality, end-use parts with comparable properties to custom plastic injection molding.

A breakthrough technology, Digital Light Synthesis uses digital light projection, oxygen permeable optics, and programmable liquid, end-use resins to produce parts with excellent mechanical properties, resolution, and surface finish. It is ideal for a range of uses.

Choose a material ideal for your application. Featuring the widest range of properties in additive manufacturing, our materials combine high-resolution, exceptional surface quality and mechanical properties tuned for production. From consumer product elastomers to high-temperature automotive materials, we are proficient in a range of materials.