Injection mold transfer—a 3‑step process

Our 3‑step Transfer Tooling Process minimizes downtime and maximizes efficiency, getting your parts back into production with minimal disruption to your business.

1. PREP Before shipment, we thoroughly review your production needs, press tonnage requirements, and associated processes to align our choice of facility and equipment to best support you. Together, we will define timelines and inventory requirements to ensure you have enough stock to fulfill orders while your mold is transferred.

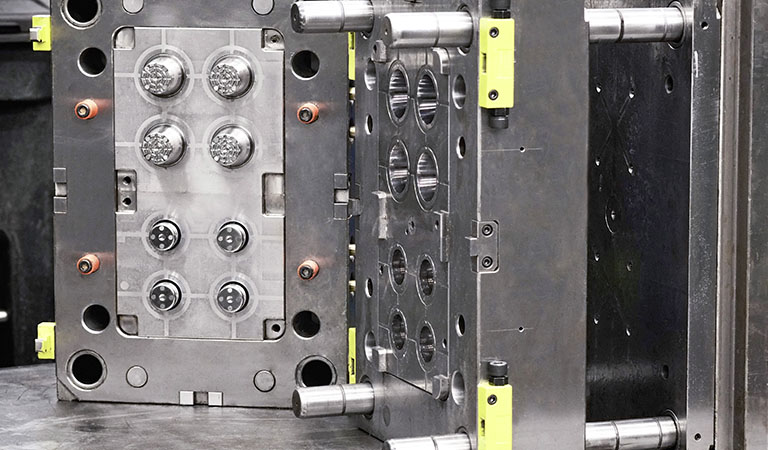

2. PM Upon receipt of your mold, we will inspect, clean, and test the mold and its components. If your mold's operating capabilities are compromised, our in‑house mold shop can implement repairs and make recommendations to improve tolerances, increase tooling integrity, or maximize efficiency.

3. PPAP After inspection, we will install your mold and test production runs to ensure product quality and operational efficiency. Whether it's First Article Inspection, PPAP, or OQ/PQ, we can work with most all part approval processes. Once the approval process is complete and samples are approved, we proceed with full scale production.