A global automotive manufacturer could not solve the significant technical challenges they faced when trying to produce their fuel-filter cap in house. The component was made from carbon-fiber-filled acetal, which the company had difficulty effectively utilizing in production. Operating in a competitive and safety-critical industry, the company contracted Thunderbird Molding to be the capable molding partner they needed to produce the complex part to its exact specifications.

The Challenge

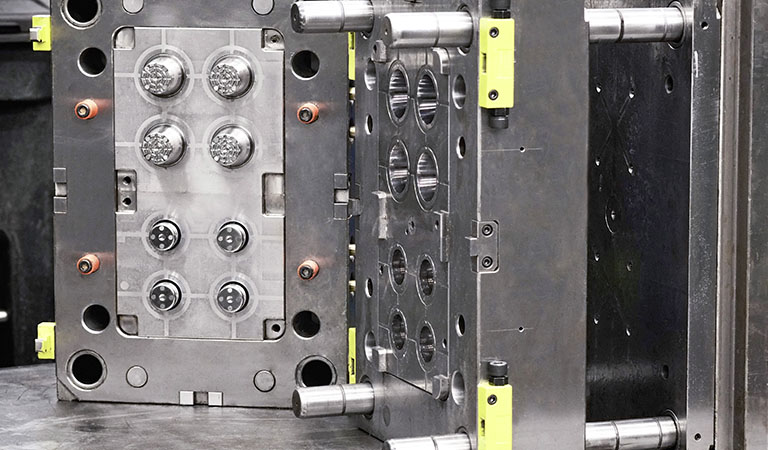

The client initially attempted to mold the fuel-filter cap internally. However, they struggled to maintain static-decay properties consistently across the component. After unsuccessful internal efforts, they decided to transfer their tooling to Thunderbird Molding. Through our Transfer Tooling Process, we coordinated to have the large mold shipped directly to our facility. We then immediately began our process of quality inspections and sampling to ensure that we could produce the component according to the client's needs.

The Solution

A major factor that contributed to our ability to overcome this challenge stemmed from our investment in advanced injection-molding technology specifically designed for technically demanding molding applications. After receiving and thoroughly inspecting the mold, we performed a detailed review and testing process to ensure no damage or contamination would compromise production. Thunderbird Molding successfully molded approved samples with our state-of-the-art technology, maintaining consistent results in conformity with the component's technical specifications.

The Impact

By solving the molding challenges of the carbon-fiber-filled acetal component, Thunderbird Molding provided the client with a compliant and fully-functional product. Throughout our collaboration with the customer, we demonstrated our value as a technically-advanced and solutions-focused partner.