A manufacturer of pool products encountered a production crisis when their original molding partner's operations were damaged from a hurricane. It was critical for them to provide a consistent supply of parts to sustain business operations and meet customer demands. With their production suddenly put on hold, they chose the dependable molding experts at Thunderbird Molding to transfer their molds and resume production.

The Challenge

The client's previous injection molder was severely impacted by a hurricane, leaving them without a facility to continue operations. The client required a fast tooling transfer and production solution to avoid any further downtime. They needed a new molding partner who could not only transfer and assess their tooling quickly but also begin production on a short timeline. We assured the client that we could minimize manufacturing downtime and be ready for production with nominal impact to their inventory and order-fulfillment operations.

The Solution

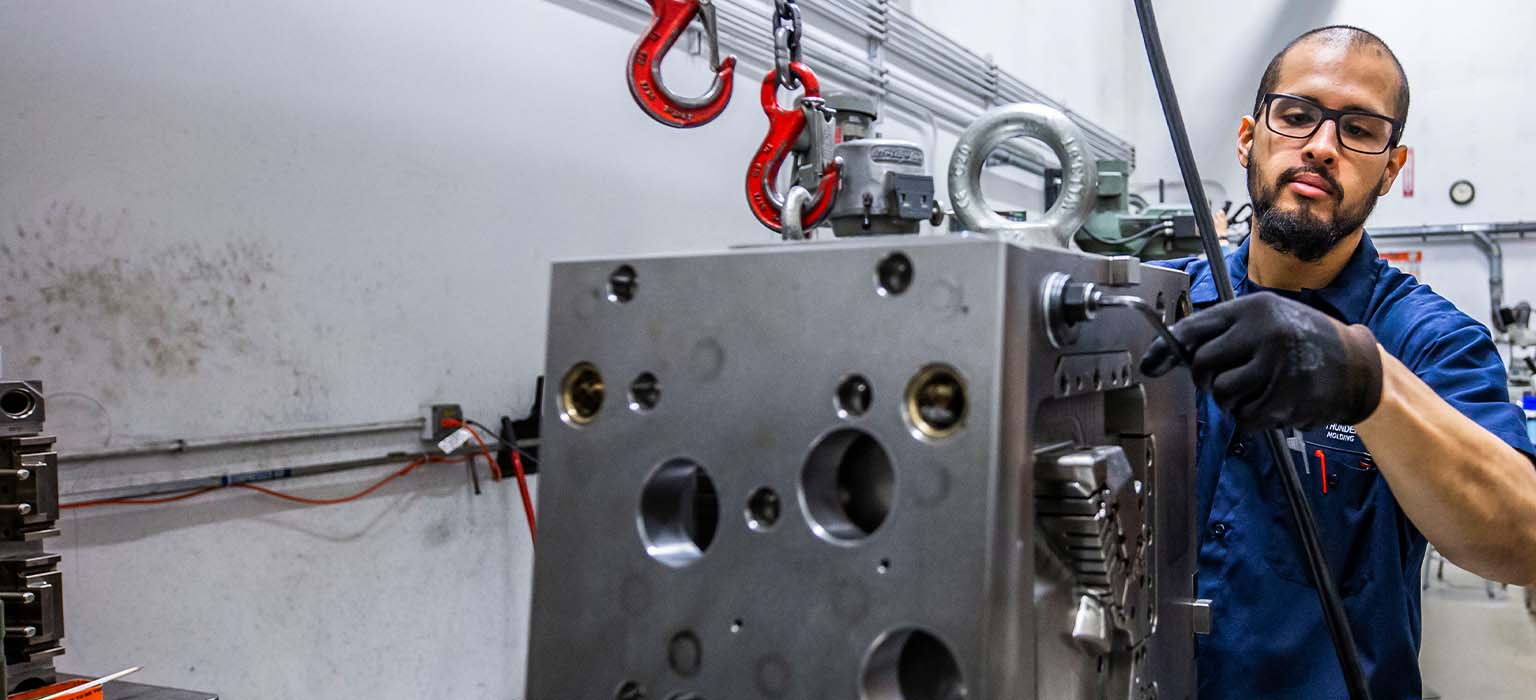

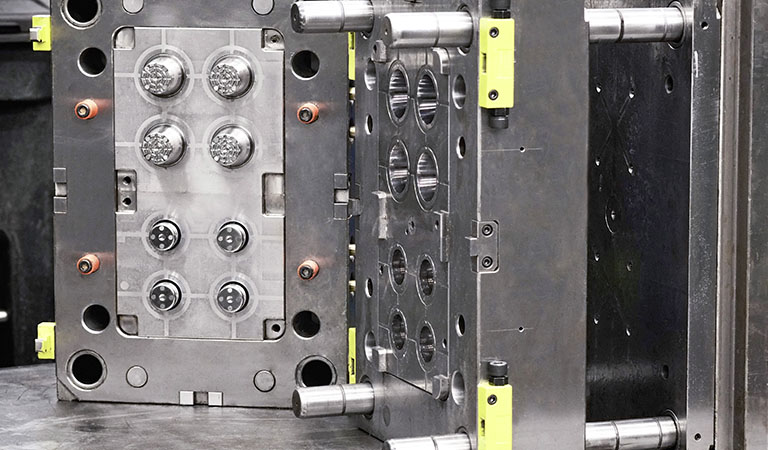

Thunderbird Molding moved swiftly to transfer the client's molds to our facility and prioritized the inspection process to minimize delays. Within just one month, we had completed a thorough test of the tooling and submitted the First Article Inspection for the client's review. We began running production parts as soon as the client approved, ensuring that their manufacturing needs were met without further interruption.

The Impact

Thanks to the efficiency of our Transfer Tooling Process we successfully took over the client's production needs and have since maintained a strong, ongoing relationship. Our responsiveness and diverse team of specialists allowed us to deliver results within the tight timeline they required.