A manufacturer of water-management products needed to transfer a sizable production program due to quality concerns with their molder. The program involved 30 molds, and the client required assurance that the transfer and ramp up to production would be completed on an aggressive timeline. As an already established client who had trusted Thunderbird Molding with other projects, the manufacturer looked to us to transfer their tooling and take over production.

The Challenge

The client was dissatisfied with the quality they were experiencing with their existing molder, but they were concerned with the scale of the change. They decided to move all 30 tools to our facility with a strict deadline, requesting that all tools be transferred, tested, set up, and back in production within six months. However, an unexpected natural disaster further complicated the project, causing a four-week delay in the tooling transfer. Our already tight timeline was reduced to just five months to accomplish the entire scope of work, making this a high-pressure, time-sensitive challenge.

The Solution

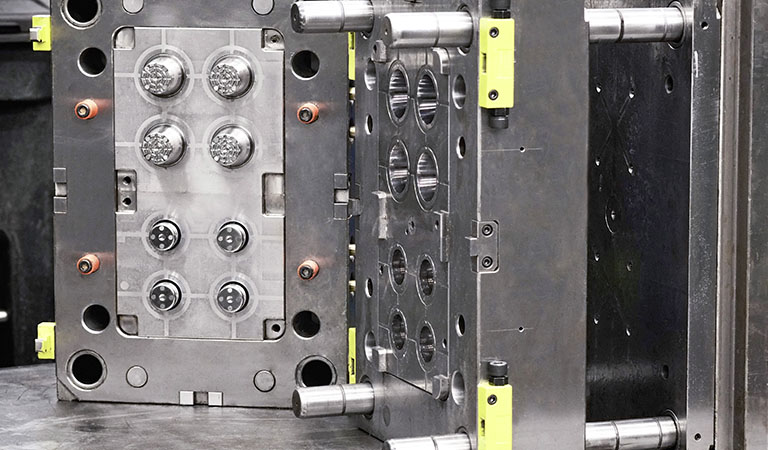

Despite the significant time constraints and unexpected setbacks, our team rose to the challenge. Through our Transfer Tooling Process, we coordinated the careful transfer of all 30 molds to our facility, where each tool underwent inspections and testing to ensure integrity and production readiness. Samples were produced and inspected to meet the client's strict quality standards. Through close collaboration and efficient problem-solving, we ensured that every tool was installed for production within the reduced five-month timeline.

The Impact

Our ability to overcome the tight timeline requirements and deliver on our commitment solidified a lasting relationship with the client. Not only did we meet their urgent needs, but our performance also demonstrated our capacity to handle large, complex transfers under pressure. Today, this client remains one of our largest customers — a testament to the trust and confidence they place in our team and capabilities.