A leading manufacturer of bolus-plug components for feeding tubes experienced significant production challenges with their in-house molding process. Operating in the highly-regulated healthcare environment, the company developed a specialized bolus plug that required exact material specifications to meet FDA patient-safety regulations. Because their in-house molding efforts did not meet regulations, the medical device manufacturer contracted Thunderbird Molding as their molding partner to transfer tooling and oversee the manufacturing process.

The Challenge

The client was under pressure to find a molder capable of producing a bolus plug that met industry and regulatory requirements. Initially attempting to mold the part in-house, they faced setbacks when the FDA required a change in the material formulation, which compromised the product's performance. Complicating matters, the bolus plug had to be manufactured using a specific compound that ensured visibility during X-rays. Maintaining the precise molecular weight and chemical composition of this specialized material proved to be a unique challenge.

The Solution

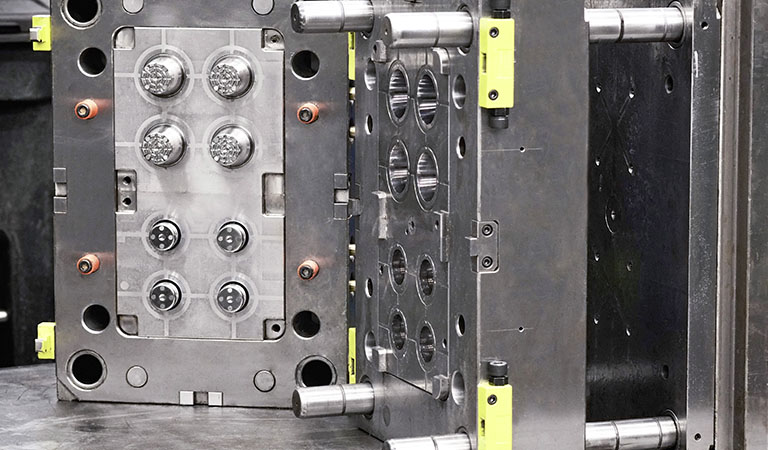

Thunderbird Molding submitted a competitive bid to manufacture the bolus plug and focused on addressing the material and regulatory challenges head-on. To achieve the necessary precision, we purchased a very specific injection-molding machine, designed to handle complex molding requirements. Three other molders were competing for the contract, but only Thunderbird Molding had the experience and equipment to meet the manufacturer's needs. We successfully molded sample parts that maintained the necessary molecular weight while also passing FDA-required testing by a third-party lab.

The Impact

Our methodical Transfer Tooling Process and unique ability to solve the material issues of this component led to its successful manufacturing, meeting all the client's regulatory and functional requirements. This success has earned Thunderbird Molding a lasting role as the injection-molding partner of this medical device manufacturer.